8021 Aluminum Foil

Alloy: AA8021

Temper:O, H12, H14, H16, H18, H22, H24, H26, H28

Thickness: 0.006-0.2mm

Size: 30-1600mm

Description

8021 Aluminum Foil Description

8021 aluminum foil oven, with one side bright and the other side dull, is a typical product of aluminum alloy used for insulation. The dull side is for adhesiveness and also having length requirement. This material with guaranteed chemical components and mechanical properties under a professional production system. XieNuo aluminum foil in toaster oven possesses good surface quality and moister-proof and abrasion resistance. 8021 aluminum foil oven liner has been tested out qualified for food and pharmaceutical grade.

| Pharmaceutical Aluminum Foil | ||||

| Alloy | Type | Temper | Thickness(mm) | Width(mm) |

| 8021 | Bare, Mill Finish | O, H14, H18 | 0.016-0.2 | 100-1600 |

8xxx series aluminum foil in convection oven is often processed into foils. 8021 aluminum foil solar oven is widely used as sealings in many containers. Such as madicine board, bottle cap, aluminium foil in microwave oven, aluminium foil in electric oven, aluminum foil on stove, etc.

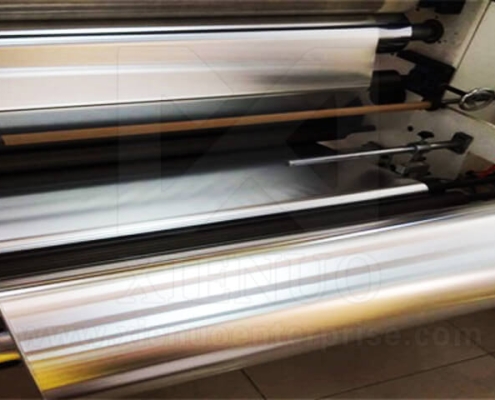

Pictures of aluminum foil sold by the factory

8021 Aluminum Foil Alloy designation (For Reference)

Comparison of Alloy Designations for 8021 aluminium foil oven liners.

| Alloy Series | Chinese Standard | American Standard | European Standard |

| 8xxx Series | 8021 | – | – |

8021 Aluminum Foil Temper designation (For Reference)

| Temper | Definition |

| O | Annealed |

| H12 | Strain Hardened, 1/4 Hard |

| H14 | Strain Hardened, 1/2 Hard |

| H16 | Strain Hardened, 3/4 Hard |

| H18 | Strain Hardened, Full Hard |

| H22 | Strain Hardened and Partially Annealed, 1/4 Hard |

| H24 | Strain Hardened and Partially Annealed, 1/2 Hard |

| H26 | Strain Hardened and Partially Annealed, 3/4 Hard |

| H28 | Strain Hardened and Partially Annealed, Full Hard |

8021 aluminium foil for stove contains lithium, so they can be a little hard, yet still flexible enough to be bent without breaking up. We can use them as aluminium foil on stove top, or aluminum foil in oven bottom.

Applications

Aluminum foil roll ensures better performance for applications such as pharmaceutical packaging, electronics packaging, battery shell, Cigarette packaging, food packaging and all of which require barrier performance.

| NAME | ALLOY | TEMPER | THICKNESS (mm) |

WIDTH (mm) |

NOTE |

| Cigarette Foil | 1235 | O | 0.006-0.007 | 200-1200 | One Side Bright |

| Household Foil | 1235,8011,8079 | O | 0.008-0.2 | 200-1400 | One Side Bright |

| Pharmacy Foil | 1235,8011,8079 | H18 | 0.0045-0.08 | 200-1400 | One Side Bright |

| Cold Forming Medicine Package Foil | 8011 8021 8079 | O | 0.045-0.075 | 200-1400 | One Side Bright |

| Food Soft Packing Foil | 8011 1235 | O | 0.006-0.03 | 200-1400 | One Side Bright |

| Container Foil | 3003,3102 8011 | H22,H24 | 0.09-0.12 | 200-1400 | Two Sides Bright |

| Cable Foil | 1235,8011,8079 | O | 0.0065-0.05 | 200-1400 | One Side Bright |

| Beer Mark foil | 8011 | O | 0.01-0.011 | 200-1400 | One Side Bright |

| Air-conditioner Foil | 8011 8006 3102 | O H22 H24 H26 | 0.07-0.100 | 200-1400 | Two Sides Bright |

| Decoration Foil | 1100 | O | 0.02-0.050 | 200-1400 | One or two side(s) bright |

Production Equipment

Production capacity: Xienuo Enterprise has a total of 25 state-of-the-art cold rolling, cast rolling, hot continuous rolling, foil rolling and extrusion production lines, including 6 casting and rolling lines, 4 continuous casting and rolling lines, and 3 coating production lines. 2 anodizing production lines, and more than 300 sets of production equipment such as rewinding machines, rounding machines, and slitting machines.

It can achieve an annual production capacity of 100,000 tons of aluminum plates, 100,000 tons of aluminum coils, 80,000 tons of aluminum foils, 50,000 tons of aluminum circle discs, and 50,000 tons of other aluminum products.

Our Services

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: The main managers in different divisions of the company all have the senior or middle titles, they will provide you the corresponding professional services.

We are here for you!