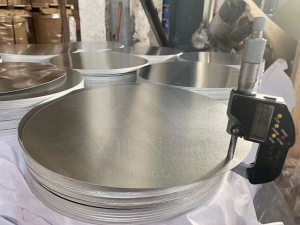

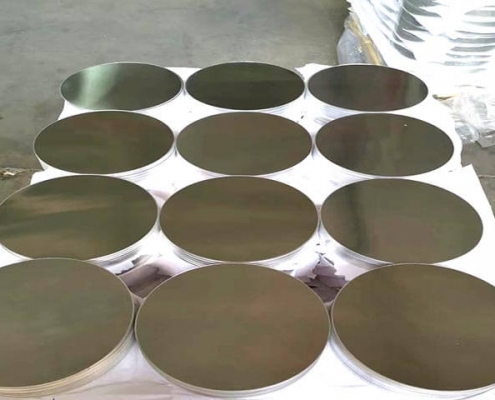

Aluminum Circle For Kitchen Cookware

Alloy:1050, 1050A, 1060, 1070, 1100,3003,3004,3105,5052 ,5083 ,5754 ,6061

Temper:O, H12, H14, H16, H18, H22, H24, H26, H28 H111, H112, H116, H321, etc.

Diameter:80mm-1500mm

Thickness:Customizable

Application of aluminum discs in cookware manufacturing

According to incomplete statistics, about half of the cookware in the world is made of aluminum. The cooking thermal efficiency is as high as 93%. Using aluminum circle to make cookware will greatly increase the physical and chemical properties of the cookware, improve the electrical conductivity, thermal conductivity, heat resistance and other properties of the cookware, providing guarantee for a good diet. .

Why use aluminum circles to make kitchen cookware?

- Aluminum circle has good thermal conductivity

Cookware needs to maintain good thermal conductivity, and aluminum pans have high thermal conductivity. When used as a production material for cookware, the produced cookware can quickly conduct heat from the fire source to the food, providing good conditions for cooking.

- The aluminum circle has strong corrosion resistance

During the process of high-temperature barbecue, the cookware must also achieve stable chemical properties. As a stable metal material, the aluminum plate itself will not rust, and some other metals will be added during the production process to make it highly durable. Corrosion resistance can resist corrosion from various substances, so that the cookware produced can meet the corresponding requirements.

- Can meet appearance requirements

Because aluminum pans are soft, they can expand significantly. Therefore, cookware made of aluminum wafers has a uniform surface particle thickness after molding, without defects such as drawing, pad printing, scratches, etc., and has a beautiful appearance.

Aluminum circles for kitchen cookware:

1050 aluminum circle CC/DC application

1050 aluminum circle has good cold forming characteristics, with an elongation between 35% and 38%, which is stable and of high value.

1060 aluminum circle CC/DC application

Common uses for 1060 aluminum discs are cookware, lampshades, and signage.

1070 aluminum circle CC/DC application

1070 alumina circle have good cold forming characteristics, stable performance and high value. Xienuo aluminum rounds can be processed into beautiful cookware or light-colored lampshades.

1100 aluminum circle CC/DC application

1100 aluminum disc has good cold working forming characteristics. The elongation is between 35%-38%. Aluminum circles are stable and more valuable.

Aluminum pan for high pressure rice cooker

3003 aluminum disc has stable and excellent formability. At the same time, the elongation rate is high and it is widely suitable for deep drawing process. The aluminum wafers we produce have high grain size and a clean luster. The aluminum wafers have high reflectivity. 3003 aluminum pans are widely used in the aluminum processing and manufacturing industry as stretched aluminum pans for cookware.

Specification

| Nominal Diameter | Tolerance |

| Multiple of 5mm | +/- 0.5mm |

| Not multiple of 5mm | +/- 3.0mm |

Classification of Aluminum Circle

- Common product specifications of cookware Aluminum circle & disc

- 2mm-3mm 1060 O, H12 cookware aluminum circle & disc suitable for frying pan, pizza pan and electric frying pan

- 2mm-4mm 3003 O aluminum circle & disc for electric pressure cooker and rice cooker

- 0.7mm-2mm 1100 O cookware aluminum circle & disc suitable for stock pots

- 3mm-5mm 1100 O aluminum disc is mainly used as the bottom of cooker and the bottom plate of stainless steel cooker

1060 Aluminum Circle

1100 Aluminum Circle CC

3003 Aluminum Circle

Production Equipment

Production capacity:Xienuo Enterprise has a total of 25 state-of-the-art cold rolling, cast rolling, hot continuous rolling, foil rolling and extrusion production lines, including 6 casting and rolling lines, 4 continuous casting and rolling lines, and 3 coating production lines. 2 anodizing production lines, and more than 300 sets of production equipment such as rewinding machines, rounding machines, and slitting machines.

It can achieve an annual production capacity of 100,000 tons of aluminum plates, 100,000 tons of aluminum coils, 80,000 tons of aluminum foils, 50,000 tons of aluminum circle discs, and 50,000 tons of other aluminum products.

Our Services

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: The main managers in different divisions of the company all have the senior or middle titles, they will provide you the corresponding professional services.

We are here for you!