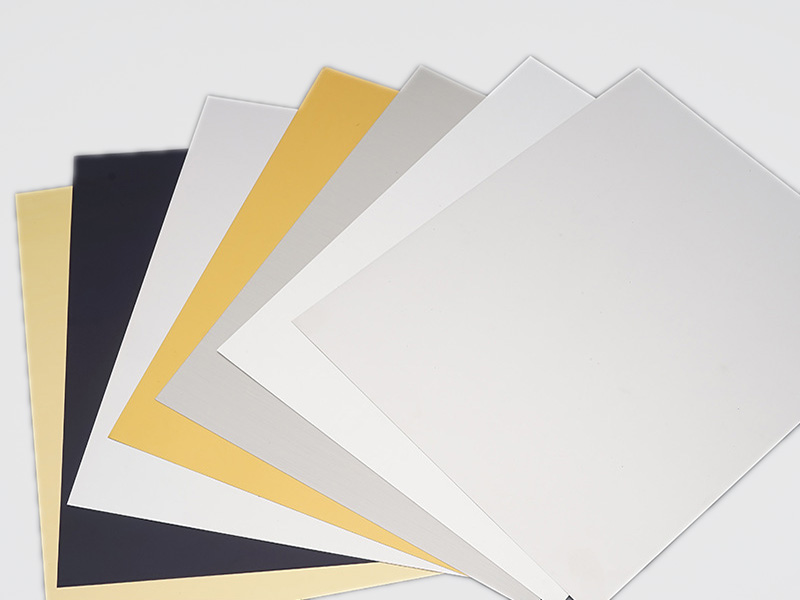

Anodized Aluminum Plate

1 series aluminum alloy: 1050 1060 1070 1100

3 series aluminum alloy: 3003 3004 3105

5 series aluminum alloy: 5005 5052 5083

6 series aluminum alloy: 6061

Temper:H114, H224, H12, H14, H16, H18, H32, H34, H36, H38, T4, T6, F

Thickness: 0.2-10.0mm

Size: (L: 900-8000mm)*(W: 900-1550mm)

Anodized aluminum production process:

In the anodizing experiment, the aluminum plate is placed in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as the anode, and electrolysis is performed under specific conditions and applied current. The aluminum plate of the anode is oxidized, and a thin layer of aluminum oxide is formed on the surface. Its thickness is 5 to 20 μm, and the hard anodized film can reach 60 to 200 μm. Anodized aluminum products have the characteristics of high hardness, good insulation, strong corrosion resistance, and strong adsorption capacity.

The anodized aluminum plate with a standard thickness oxide film (3μm) will not discolor, corrode, oxidize or rust when used indoors for a long time. The anodized aluminum plate with thickened oxide film (10μm) can be used outdoors and will not discolor after being exposed to sunlight for a long time. The product can be continuously stamped at high speed, which is convenient for direct processing into products. There is no need for complex surface treatment, which greatly shortens the product production cycle and reduces product production costs.

Performance characteristics of anodized aluminum:

Good processability: Anodized aluminum plates have high decorative performance, moderate hardness, and are easy to bend and form. High-speed stamping continuity facilitates direct processing into products without complex surface treatment, which greatly shortens the production cycle and reduces production costs.

Good weather resistance: anodized aluminum plate, standard oxide film thickness (3μm), no discoloration, no corrosion, no oxidation, no rust when used indoors for a long time. Those with a thickened oxide film (10μm) can be used outdoors and will discolor after long-term exposure to sunlight.

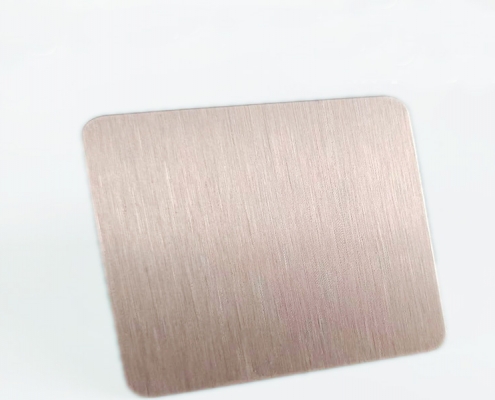

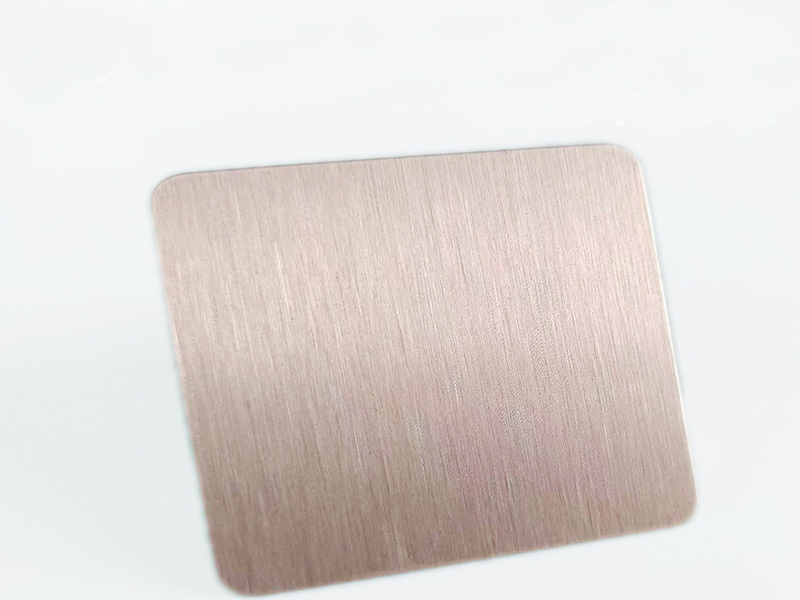

Strong metallic feel: Anodized aluminum has high surface hardness, reaching gem level, high scratch resistance, no paint coverage on the surface, maintaining the original color of aluminum metal, and improving product quality and added value.

Application for anodized aluminum

Anodized aluminum has high applicability and can be used in: metal aluminum ceilings, curtain wall panels, fireproof panels, aluminum veneers, electrical panels, cabinet panels, furniture panels, etc.

Production Equipment

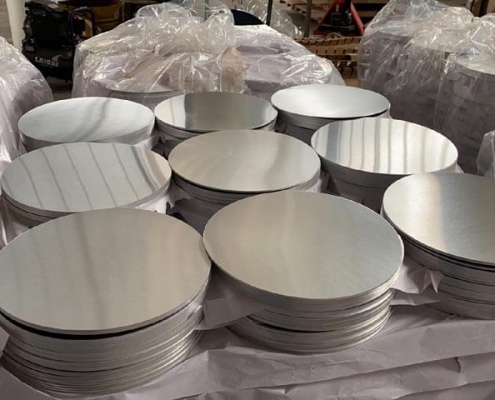

Production capacity:Xienuo Enterprise has a total of 25 state-of-the-art cold rolling, cast rolling, hot continuous rolling, foil rolling and extrusion production lines, including 6 casting and rolling lines, 4 continuous casting and rolling lines, and 3 coating production lines. 2 anodizing production lines, and more than 300 sets of production equipment such as rewinding machines, rounding machines, and slitting machines.

It can achieve an annual production capacity of 100,000 tons of aluminum plates, 100,000 tons of aluminum coils, 80,000 tons of aluminum foils, 50,000 tons of aluminum circle discs, and 50,000 tons of other aluminum products.

Our Services

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: The main managers in different divisions of the company all have the senior or middle titles, they will provide you the corresponding professional services.

We are here for you!