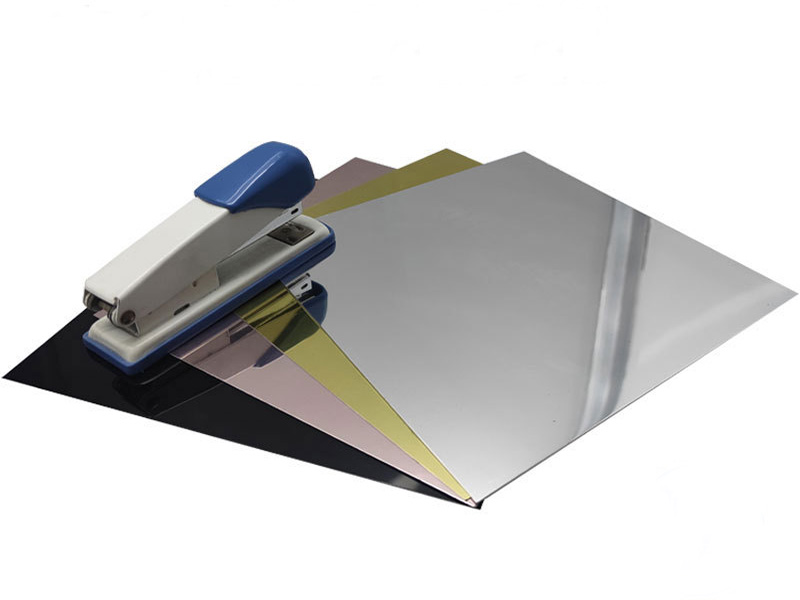

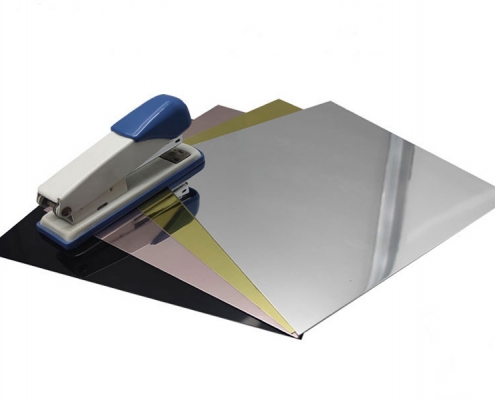

Polished Aluminum Mirror Sheet

1 series aluminum alloy: 1050 1060 1070 1100

3 series aluminum alloy: 3003 3004 3105

5 series aluminum alloy: 5005 5052 5083

6 series aluminum alloy: 6061

Temper:H114, H224, H12, H14, H16, H18, H32, H34, H36, H38, T4, T6, F

Thickness: 0.2-10.0mm

Size: (L: 900-8000mm)*(W: 900-1550mm)

Mirror polished aluminum plate production process:

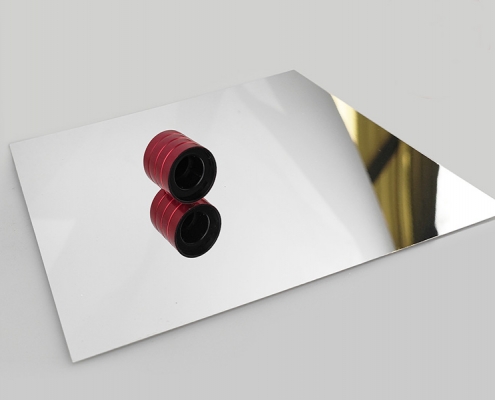

Mirror aluminum plate refers to an aluminum plate that is processed by various methods such as rolling and grinding to give the surface of the plate a mirror effect.

There are many types of mirror aluminum plates, from low to high, there are ordinary polished aluminum plates, mirror anodized aluminum plates and super mirror aluminum plates.

1. Surface treatment

Surface treatment is a key step in making mirror aluminum plates, which directly affects the color and quality of the product. Generally, chemical or mechanical methods are used to treat the surface of the board. Chemical methods generally use pickling, alkali cleaning, electrolytic polishing, etc., while mechanical methods can use sand brushing, polishing, etc.

2. Coating

Coating is to enhance the anti-corrosion performance and surface hardness of the mirror aluminum plate, and is generally processed by methods such as anodizing. During this process, a dense oxide film will be formed on the surface of the aluminum plate, which improves its corrosion resistance, wear resistance and oxidation resistance.

3. Polishing

Polishing is to make the surface of the aluminum plate smoother and brighter. Generally, mechanical polishing and manual polishing are used. Mechanical polishing mainly uses machines for high-speed friction to grind and polish the matte and bright areas on the surface of the mirror aluminum plate to achieve a flat and smooth effect; while manual polishing requires workers to use polishing pads, abrasive slurries and other auxiliary tools. Polishing and sanding.

The above is the main process flow of mirror aluminum plate production. In actual production, material selection, cutting, splicing, drilling, installation and other steps also need to be carried out.

Features of Mirror reflective aluminum plate:

1. Weather resistance: Using fluorocarbon spray and high-quality polyester paint or epoxy resin paint, it can maintain long-term discoloration and powdering, and has a long service life.

2. Good self-cleaning property: It has self-cleaning performance unmatched by ordinary paints;

3. Strong stain resistance: does not stick to oil, does not stick to water, and prevents pollution;

4. Good craftsmanship: uniform coating and various colors;

5. Good adhesion and flexibility: excellent scratch resistance enables it to withstand strong impact;

6. Good flatness (especially applied to curved and special-shaped products): low requirements on the base surface during construction (even without leveling), and has good plane stability.

Applications of Polished Aluminum Mirror Sheet:

Mirror aluminum plates are widely used in lighting reflectors and lamp decorations, solar collector reflective materials, indoor architectural decoration, exterior wall decoration, household appliance panels, electronic product casings, furniture kitchens, automobile interior and exterior decoration, signs, logos, bags, and jewelry. boxes and other areas.

Production Equipment

Production capacity: Xienuo Enterprise has a total of 25 state-of-the-art cold rolling, cast rolling, hot continuous rolling, foil rolling and extrusion production lines, including 6 casting and rolling lines, 4 continuous casting and rolling lines, and 3 coating production lines. 2 anodizing production lines, and more than 300 sets of production equipment such as rewinding machines, rounding machines, and slitting machines.

It can achieve an annual production capacity of 100,000 tons of aluminum plates, 100,000 tons of aluminum coils, 80,000 tons of aluminum foils, 50,000 tons of aluminum circle discs, and 50,000 tons of other aluminum products.

Our Services

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: The main managers in different divisions of the company all have the senior or middle titles, they will provide you the corresponding professional services.

We are here for you!