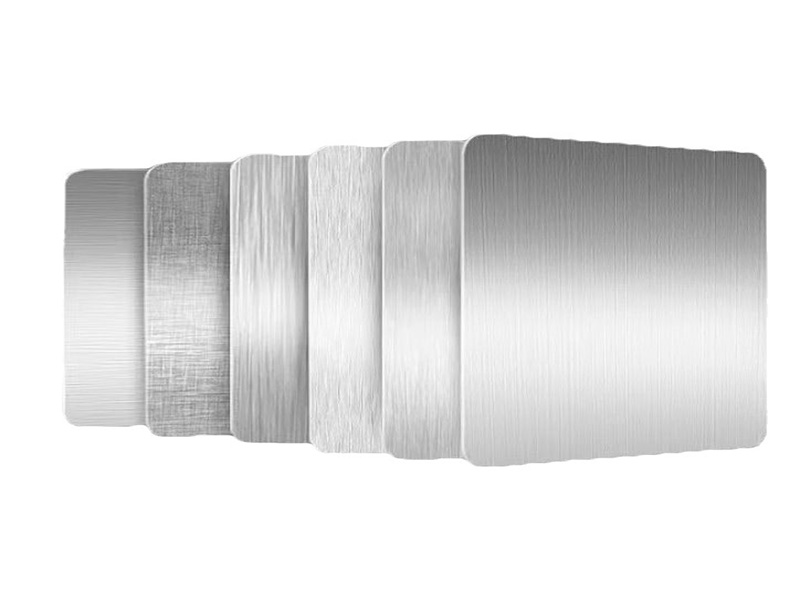

Brushed Aluminum Plate

1 series aluminum alloy: 1050 1060 1070 1100

3 series aluminum alloy: 3003 3004 3105

5 series aluminum alloy: 5005 5052 5083

6 series aluminum alloy: 6061

Temper:H114, H224, H12, H14, H16, H18, H32, H34, H36, H38, T4, T6, F

Thickness: 0.2-10.0mm

Size: (L: 900-8000mm)*(W: 900-1550mm)

Brushed aluminum plate production process:

Brushed aluminum uses (physical treatment) mechanical friction or extrusion to process straight lines on the surface of the aluminum plate. Drawing treatment is done after stamping. Drawing can be made into straight lines, random lines, threads, corrugations and spiral lines according to the decoration needs.

Brushed aluminum plate is a manufacturing process in which lines are repeatedly scraped out of the aluminum plate with sandpaper. The main process of the process is divided into three parts: deesterification, sand mill and water washing. In the aluminum plate drawing process, the special film technology after anodizing can generate a film layer containing the metal component on the surface of the aluminum plate, clearly showing every tiny trace, thereby making the metal matte appear fine hair. Silky luster.

More and more aluminum plate products use metal brushing technology for their metal casings to provide aesthetics and corrosion resistance, making the products have both fashion and technology elements.

Advantages of brushed aluminum plates:

- Anti-corrosion

Due to various surface treatments, the brushed aluminum plate can effectively prevent oxidation and extend its service life. At the same time, the surface of the brushed aluminum plate is smooth, has good anti-fouling properties, and is not easy to adhere to dust, stains, etc.

- Wear resistance

The surface of the brushed aluminum plate is brushed to make it more wear-resistant. Due to the drawing treatment, tiny scratches are produced on the surface of the aluminum plate, making the surface of the aluminum plate more uniform and smooth. In addition, brushed aluminum plates have higher hardness and strength and have better resistance to extrusion.

- Beautiful

The surface of the brushed aluminum plate shows a delicate brushed texture, which shows an alternating effect of light and dark under the sun, making it particularly beautiful. Moreover, the brushed aluminum plate can be customized in different colors, thicknesses, and sizes according to needs, and has high plasticity.

- Environmental protection

The brushed aluminum plate is non-toxic and odorless and meets environmental protection standards. At the same time, aluminum is highly recyclable and can effectively reduce environmental pollution.

Brushed aluminum veneer is produced through processes such as wire drawing or electric corrosion, and the price is higher than ordinary spray-painted panels;

The surface of the brushed aluminum veneer adopts metal brushing technology, which can significantly reduce finger marks, has a good matte effect and has a strong visual impact.

Color of brushed aluminum plate:

Bronze, green, stainless steel, blue red, silver, gold, black, pink, brass, bronze, matte and other colors. Colors can be customized according to customer needs.

Applications of brushed aluminum plates:

Brushed aluminum panels have many advantages such as corrosion resistance, wear resistance, beauty, and environmental protection. They are widely used in brushed aluminum-plastic panels, fireproof panels, aluminum photo frames, integrated ceilings, boutique cabinets, boutique doors and windows, veneer panels, signs, lighting, and indoor and outdoor decoration. , building curtain walls, household appliances, bags, gifts, furniture, consumer electronics and other fields.

Production Equipment

Production capacity: Xienuo Enterprise has a total of 25 state-of-the-art cold rolling, cast rolling, hot continuous rolling, foil rolling and extrusion production lines, including 6 casting and rolling lines, 4 continuous casting and rolling lines, and 3 coating production lines. 2 anodizing production lines, and more than 300 sets of production equipment such as rewinding machines, rounding machines, and slitting machines.

It can achieve an annual production capacity of 100,000 tons of aluminum plates, 100,000 tons of aluminum coils, 80,000 tons of aluminum foils, 50,000 tons of aluminum circle discs, and 50,000 tons of other aluminum products.

Our Services

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: The main managers in different divisions of the company all have the senior or middle titles, they will provide you the corresponding professional services.

We are here for you!