5754 Aluminum Plate

Alloy: AA5754

Temper:O, H12, H14, H16, H18, H22, H24, H26, H28, H32, H111, H114

Thickness: 3-600mm

Size: W(500-2800mm)*L(500-6000mm)

Description

5754 Aluminum Plate DC / CC Alloy designation (For Reference)

Comparison of Alloy Designations for Aluminum Flat Sheet. Standards: ASTM-B209. EN573-1, GB/T3880.1-2006.

| Alloy Series | Chinese Standard | American Standard | European Standard |

| 5xxx Series | 5754 | 5754 | EN AW-5754 |

5754 Aluminum Plate DC / CC Chemical Compositing

Chemical Composition conforms to Chinese, American and European standard specification (For Reference)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others:Each | Others:Total | Al:Min. |

| 5754 | 0.4 | 0.4 | 0.1 | 0.5 | 2.6-3.6 | 0.3 | 0.2 | 0.15 | 0.05 | 0.15 | remainder |

5754 aluminum plate has a high adaptability to high fatigue strength and weldability. In terms of composition, the 5754 aluminum plate contains elements such as magnesium, zinc, manganese, chromium, iron, and silicon. Its tensile strength is 165-265mpa, which is attributed to medium level. The 5754 alloying element is mainly Mg, and the Mg content is between 3-5%. The main features are low density and high elongation. Therefore, under the same area, the lightweight value is high.

5754 Aluminum Plate Mechanical Properties

| Alloy And Temper | Tensile Strength Rm / Mpa |

Yield Strength Rp0.2 / Mpa |

Elongation / % | Hardness / HBWα |

| 5754-O | 190-240 | 80 | 12 | 38 |

5754 aluminum alloy with moderate strength, good corrosion resistance, weldability and ease of processing forming characteristics such as Al-Mg alloy typical alloys. As a wrought alloy, it can be formed by rolling, extrusion, and forging, but not casting. It can be cold worked to produce tempers with a higher strength but a lower ductility. 5754 Alloy has good machinability in cold work hardening and half cold work hardening condition, and not good machinability in annealing state, can be polished.

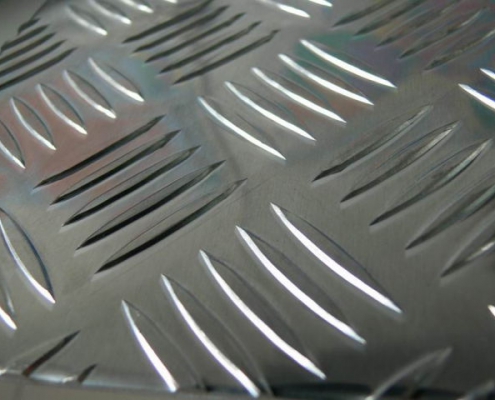

5754 Aluminum Plate DC / CC Temper Types

The most common tempers for 5754 Aluminum Plate are shown below with H114 & H111 being the most common treadplate temper

| Temper | Definition |

| O | Soft |

| H12 | Strain Hardened, 1/4 Hard |

| H14 | Strain Hardened, 1/2 Hard |

| H16 | Strain Hardened, 3/4 Hard |

| H18 | Strain Hardened, Full Hard |

| H22 | Strain Hardened and Partially Annealed, 1/4 Hard |

| H24 | Strain Hardened and Partially Annealed, 1/2 Hard |

| H26 | Strain Hardened and Partially Annealed, 3/4 Hard |

| H28 | Strain Hardened and Partially Annealed, Full Hard |

| H32 | Work hardened by rolling then stabilised by low-temperature heat treatment to quarter hard |

| H111 | Some work hardening imparted by shaping processes but less than required for H11 temper |

5754 Aluminum Plate DC / CC Applications

5754 thick aluminum plate is widely used in precision mold, storage tanks, pressure vessels, ship structures and offshore facilities, transportation tanks, as well as in applications requiring excellent machining performance, excellent corrosion resistance, high fatigue strength, high weldability and medium static strength.

| Type | Application |

| Construction | ACP sheet, Curtain walls, cladding, ceiling, heat insulation and venetian blind block, etc. |

| Transportation | Automobile parts, bus bodies, aviation and ship-building and air-cargo containers, etc. |

| Electronic Appliance | Electric fan blade, Electrical appliances, phone shell, PCB board drilling guide sheets, lighting and heat radiating materials, etc. |

| Other | Precision mold, oil tank, storage tanks, pressure vessels, car license, auto body |

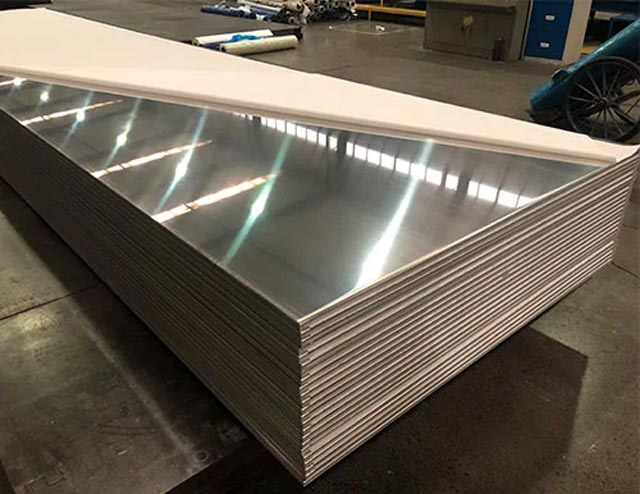

5754 Aluminum Plate DC / CC Available Size Range

In the form below are some parameters of our products. But the aluminum plate thickness and the aluminum plate weight per piece are all customizable.

| Dimension | Range |

| Thickness | 0.2-100mm |

| Width | 500-2800mm |

| Length | 500-6000mm |

* Surface Finish: Mill finish, unless otherwise specified

* Surface Protection: Paper interleaved, PE/PVC filming (if specified)

Production Equipment

Production capacity:Xienuo Enterprise has a total of 25 state-of-the-art cold rolling, cast rolling, hot continuous rolling, foil rolling and extrusion production lines, including 6 casting and rolling lines, 4 continuous casting and rolling lines, and 3 coating production lines. 2 anodizing production lines, and more than 300 sets of production equipment such as rewinding machines, rounding machines, and slitting machines.

It can achieve an annual production capacity of 100,000 tons of aluminum plates, 100,000 tons of aluminum coils, 80,000 tons of aluminum foils, 50,000 tons of aluminum circle discs, and 50,000 tons of other aluminum products.

Our Services

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: The main managers in different divisions of the company all have the senior or middle titles, they will provide you the corresponding professional services.

We are here for you!