Aluminum Foil For Aluminum Foil Containers

Alloy:3003 8011

Temper:O, H12, H14, H16, H18, H22, H24, H26, H28 H111, H112, H116, H321, etc.

Thickness:Customizable

Aluminum foil containers are a widely used type of tableware, and the main material is aluminum foil. There is a dense oxide layer on the surface of aluminum foil. Its chemical properties are relatively stable. No bacteria and microorganisms can grow on its surface. It is environmentally friendly and easy to recycle.

Production material Aluminum foil is rolled from aluminum alloy raw materials through multiple processes and does not contain harmful substances. Therefore, aluminum foil containers are safe for food contact. In most cases, aluminum foil will not react with food.

What is the principle of aluminum foil being processed into lunch boxes?

Aluminum foil containers withstand temperature changes well during processing and packaging. The molecular structure is stable at high and low temperatures of -20°C to 250°C, and the use temperature range can range from quick freezing to baking and grilling. During this time, the aluminum foil will not deform, crack, melt or burn, and no harmful substances will be produced. Use aluminum foil to separate high-temperature charcoal fire and smoke to avoid burning food and producing carcinogens.

Aluminum foil lunch boxes and containers are ideal for high temperature sterilization and heat sealing. Aluminum foil lunch box containers can be heated in a variety of ways, including various ovens, ovens, anaerobic heating cabinets, steamers, steamers, microwaves (light waves and grills must be used), and pressure cookers to heat aluminum-wrapped food frustrations. Relevant companies have developed supporting secondary heating equipment and packaging equipment for aluminum foil lunch boxes. Aluminum foil lunch box manufacturers can greatly improve the distribution efficiency and food quality of catering companies.

What are the commonly used alloy grades for aluminum foil lunch boxes?

Aluminum foil lunch boxes are disposable lunch boxes made of aluminum foil. It has the characteristics of light material, high barrier property, UV resistance, moisture-proof and anti-corrosion, and long shelf life. They retain food freshness and moisture better and can be heated directly.

Aluminum foil containers are made of food-grade 3003, 3004, and 8011 alloy aluminum foil. It has the characteristics of non-toxic and harmless, safe and hygienic, high and low temperature resistance, green and environmentally friendly, renewable and energy-saving, good sealing, convenient and fast.

The thickness of aluminum foil containers is generally between 0.03mm-0.20mm, and can be divided into wrinkled and wrinkle-free.

Aluminum foil container use 3003 alloy, and high-end lunch boxes, especially export aluminum foil containers, still use 3003 aluminum foil.

In order to reduce costs, 8011 Aluminum foil alloy has also begun to be used in aluminum foil containers. The reduction in cost further promoted and used aluminum foil as a lunch box material, but it also made the strength of the lunch box significantly lower than that of 3003 alloy.

On the other hand Aluminum foil containers produced with 3004 aluminum foil not only ensure the low price of 8011 alloy, but also ensure the high strength characteristics of 3003 alloy. The strength of 3004 aluminum foil alloy is higher than that of 3003 alloy.

What are the performance advantages of aluminum foil for aluminum foil containers?

In conclusion Contains the following points

- Various sizes, specifications, colors and shapes can be customized.

- Safe, hygienic, easy to heat, no harmful substances are produced after heating, and the product has a wide range of practical applications

- Beautiful appearance, light texture, easy to form and seal, ensuring food hygiene.

- It has strong barrier properties. After sealing, it can protect the original flavor of the food and extend the shelf life of the food.

- It can be recycled and reused efficiently, no harmful substances are produced during the treatment process, no renewable resources are polluted, the environment is protected, and resources are saved.

- Various heating and storage methods: open flame heating, microwave heating, refrigerated storage, etc.

Aluminum foil specifications for aluminum foil containers

| Alloy | Temper | Thickness (mm) |

Width (mm) |

| 30003,3004 | O、H22、H24、H26 | 0.02mm and above | Customized |

| 8011 | O、H22、H24、H26 | 0.02mm and above | Customized |

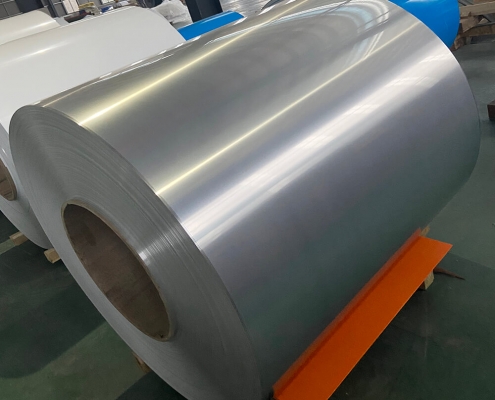

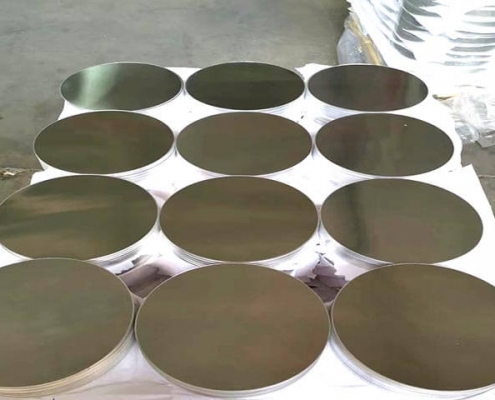

Production Equipment

Production capacity: Xienuo Enterprise has a total of 25 state-of-the-art cold rolling, cast rolling, hot continuous rolling, foil rolling and extrusion production lines, including 6 casting and rolling lines, 4 continuous casting and rolling lines, and 3 coating production lines. 2 anodizing production lines, and more than 300 sets of production equipment such as rewinding machines, rounding machines, and slitting machines.

It can achieve an annual production capacity of 100,000 tons of aluminum plates, 100,000 tons of aluminum coils, 80,000 tons of aluminum foils, 50,000 tons of aluminum circle discs, and 50,000 tons of other aluminum products.

Our Services

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: The main managers in different divisions of the company all have the senior or middle titles, they will provide you the corresponding professional services.

We are here for you!