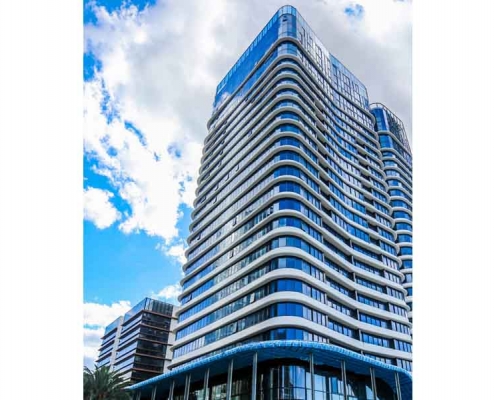

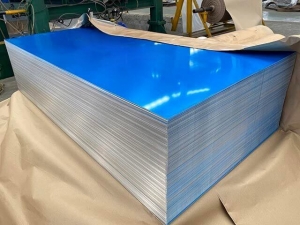

Aluminum products for aluminum veneer curtain wall

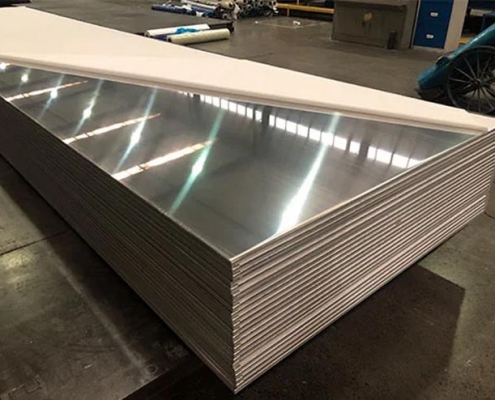

Alloy:1050 1060 1100 3003 5052 5083 5754 6061

Temper:O, H12, H14, H16, H18, H22, H24, H26, H28 H111, H112, H116, H321, etc.

Thickness:Customizable

Surface:Mill finish surface, Color coated surface, Anodized surface.

Shape:Horizontal rectangle, Vertical rectangle, Square,Circle, Triangle, Pentagon, Octagon.

Aluminum alloy composition

Aluminum alloy is pure aluminum composed of magnesium (Mg), manganese (Mn), copper (Cu), silicon (Si) and some other elemental alloy additives. Aluminum alloys are widely used in construction, aircraft manufacturing, and even aerospace fields due to their excellent physical and chemical properties.

The aluminum veneer curtain wall is made of aluminum alloy and is processed according to the current national standard “Aluminum Alloy Building Profiles” GB5237-2000.

Advantages of using aluminum alloy for aluminum veneer curtain wall

Compared with other metal materials, aluminum veneer curtain walls use aluminum and aluminum alloys and have the following characteristics:

- Low density: The density of aluminum and aluminum alloys is close to 2.7g/, which is about 1/3 of iron or copper.

- High strength: The strength of the matrix can be strengthened through a certain degree of cold working, and some brands of aluminum alloys can also be strengthened through heat treatment.

- Good electrical and thermal conductivity: The electrical and thermal conductivity of aluminum is second only to silver, copper and gold.

- Good corrosion resistance: The surface of aluminum is easy to naturally produce a dense and strong protective film of AL2O3, which can well protect the substrate from corrosion.

- Easy processing: After adding certain alloy elements, cast aluminum alloys with good casting properties or deformed aluminum alloys with good processing plasticity can be obtained.

What are the commonly used aluminum alloy grades for aluminum veneer curtain walls?

1000 series aluminum plate coils, 3000 series aluminum plate coils, and 5000 series aluminum plate coils are used as base materials, with various thickness specifications such as 1.2mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm, and 4.0mm.

The reason why aluminum alloy is often chosen as building exterior decoration materials is because of its light weight, high strength, good corrosion resistance, easy processing, rich color changes and many other advantages.

1000 series aluminum veneer curtain wall commonly used aluminum alloy series

The 1000 series aluminum content is greater than 99.0%, making it softer than other aluminum alloys and easier to manufacture. Among them, the alloy grades 1050 1060 1100 aluminum plate or 1050 1100 1060 aluminum coil have a wide range of applications.

Advantages and uses of 1000 series aluminum plates and coils

Series 1 aluminum plates or aluminum coils refer to aluminum alloys containing aluminum elements with higher purity, usually above 99%. This aluminum plate has excellent corrosion resistance, electrical conductivity, thermal conductivity and processability, so it is widely used in various fields.

The main uses of Series 1 aluminum plates and coils are as follows:

Series 1 aluminum panels are lightweight, corrosion-resistant, and easy to process, so they are widely used in the construction field. For example, used in building exterior walls, roofs, ceilings, partitions, doors and windows, etc. In addition, 1 series aluminum plates can also be used in building decoration materials, such as aluminum alloy curtain walls, aluminum alloy ceilings, etc.

1050 Aluminum Sheet

1060 Aluminum Sheet

1100 Aluminum Coil CC

3000 series aluminum veneer curtain wall commonly used aluminum alloy series

3 series aluminum alloy is also called aluminum-manganese alloy. The content of manganese element is 1-1.5%. It is a widely used anti-rust aluminum alloy series. The strength of 3 series aluminum alloy is higher than that of pure aluminum alloy. It is suitable for cold processing (super cold rolling). It has good plasticity after machine rolling) and annealing process. Because of its good corrosion resistance and welding performance, it is widely used in the building decoration industry.

Advantages and uses of 3000 series aluminum plates and coils

The main brands commonly used in 3 series aluminum alloys are 3003 aluminum plate, 3003 aluminum coil, 3004 aluminum plate, 3004 aluminum coil, etc.

Among them, the largest amount of aluminum alloy is 3003. 3003 aluminum plates and coils are easy to process and have good rust resistance. Colorful paint can be rolled on the surface of raw aluminum to make various decorative curtain wall panels and indoor aluminum ceiling gussets. It can also be bent by a tile press to make roof colored aluminum tiles, which are lightweight and durable, and have a longer lifespan than steel.

3003 Aluminum Sheet

3003 Aluminum Coil

3004 Aluminum Coil

5000 series aluminum veneer curtain wall commonly used aluminum alloy series

5 series aluminum plate is a common aluminum alloy plate with excellent performance and wide range of uses. It is mainly composed of aluminum, zinc, magnesium, copper and other elements, and has the characteristics of high strength, corrosion resistance, oxidation resistance, and good thermal conductivity.

Advantages and uses of 5000 series aluminum plates and coils

Commonly used alloy grades include: 5052, 5083, 5454, 5754 aluminum plate or 5754, 5083, 5454, 5052 aluminum coil.

Because 5 series aluminum plates have good corrosion resistance and oxidation resistance and can withstand various harsh climatic conditions, they are widely used in building exterior walls, roofs, ceilings and other decorative materials. It can provide a variety of colors and surface treatments to make buildings more beautiful and durable.

5052 Aluminum Plate

5083 Aluminum Plate

5754 Aluminum Coil

Production Equipment

Production capacity: Xienuo Enterprise has a total of 25 state-of-the-art cold rolling, cast rolling, hot continuous rolling, foil rolling and extrusion production lines, including 6 casting and rolling lines, 4 continuous casting and rolling lines, and 3 coating production lines. 2 anodizing production lines, and more than 300 sets of production equipment such as rewinding machines, rounding machines, and slitting machines.

It can achieve an annual production capacity of 100,000 tons of aluminum plates, 100,000 tons of aluminum coils, 80,000 tons of aluminum foils, 50,000 tons of aluminum circle discs, and 50,000 tons of other aluminum products.

Our Services

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: The main managers in different divisions of the company all have the senior or middle titles, they will provide you the corresponding professional services.

We are here for you!