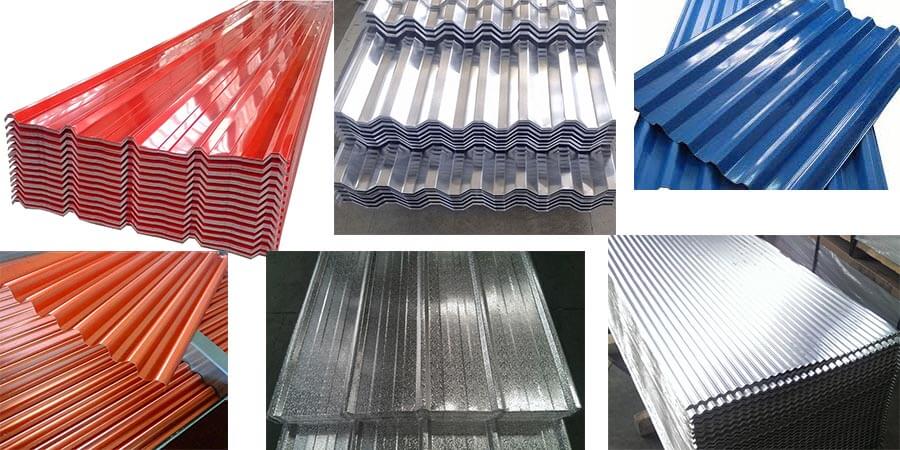

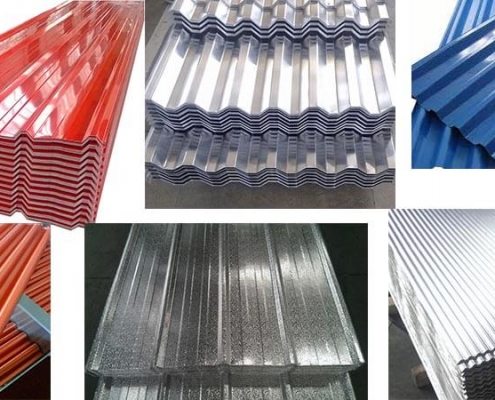

Aluminum Roofing Sheet

Alloy: 1100, 3003, 3004, 3105, 5006, 5052, 8011

Temper:O, H12, H14, H16, H18, H22, H24, H26, H28

Thickness:0.08-4.0mm

Size: custom made

Description

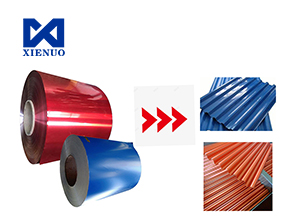

Color coated aluminum coils for roofing sheets are of alloys 1050, 1060, 1100, 3003, 3004 and 3105. Although there are 6 candidate alloys, only 3003 and 3004 are the most popular. 1050, 1060 and 1100 are weaker in either hardness or corrosion resistance.

They are suitable for roofing sheets expected to last only years, especially when they are coated with PE paint. PVDF coated aluminium roofing coil rolls usually last much longer, over 20 years with an ideal thickness.

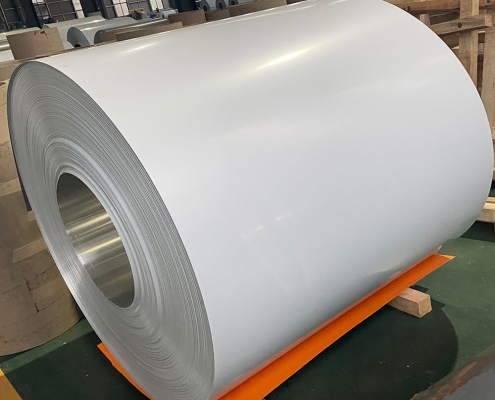

The tempers of the coils include H46 and H44, and the thickness ranges from 0.3mm to1.5mm, and width 600mm to 1250mm.

The color coated aluminum roofing sheet coil is featured by low weight, good corrosion resistance and outstanding processing ability. In comparison to stone and pottery roofing sheets, aluminium sheets are much lighter, which indicates convenient installation and maintenance. Good corrosion resistance is an exclusive advantage of aluminium coil over other roofing materials. What’s more, the color coated aluminium coils for roofing sheets have durable and weather resistant coating of resin paints. This extends their service life substantially. Last but not least, the coated aluminum rolls will have to be bent and perforated before being made into roofing sheets, and the sheets need to be drilled for installation. 1000 and 3000 series of aluminium coils have proper elongation and hardness, just perfect for such processing methods. That’s why aluminium roofing sheets become increasingly popular.

Specifications of Coloured Coated Aluminum Sheet:

| Alloy: | AA1100, 3003, 3004, 3105, 5006, 5052, 8011 |

|---|---|

| Thickness: | 0.08-4.0mm |

| Width: | <1800mm |

| Coils core diameter: | 150mm ,405mm, 505mm, 508mm, 510mm |

| Coating thickness: | PVDF >=25micron POLYESTER>=18micron |

| Color standard: | E < 2 or it is not obvious by eyeballing |

| Pencil hardness: | > 2HB |

| Coating adhesive: | not lower than first grade Impact: no any crack (50kg/cm, ASTMD-2794:1993) |

| Bend stength: | >100 times |

| Boiling point: | no any distortion and color change (in the 99 more or less 1 degree water, then cooling 2 hours) |

| Corrosive: | surface deep in the 5% muriatic acid and 5% NaCL, interior deep in the 2% muriatic acid and 2% NaCL, after 48 hours, no change |

Applications of Color Coated Aluminum Sheet:

For its lightweight, beautiful appearance, as well as good anti-correction, color coated aluminum Sheet and Coil are vastly used in Exterior and Interior applications. Color coated aluminum coil are widely used in ACP,curtain panel,honey comb panel,shutter,roofing and most of the decoration areas.

| Building | Venetian blinds, rolling shutters, ceiling panels, roofing, façade, ACP Panel. Eveas etc. |

| Roller Shutter | Aluminium Composite Panel (ACP), Ceiling, Roofing etc |

| Industry | an ideal material for white appliances such as refrigerator due to it’s property of electrical and thermal conductivity, and corrosion resistance |

| Transport | truck body, caravan, buses, insulated and refrigerated vehicle |

| Signs | Application in Signs requires high colour consistency and flat surface. UAL can fulfill the requirements with excellent performance. |

Xienuo guarantees the minimum coating thickness of 18um for pe and 25um for pvdf. The color of the coil can be customized. Usually we follow the color card of RAL9006, RAL9016, RAL9007, RAL7039, RAL7035 and RAL7021. In addition, the bending hardness, pencil hardness, boiling resistance and service life can be guaranteed, too. The price of the color coated aluminum coils for roofing sheets has been rising with that of raw material and manufacturing cost, and it fluctuates daily. Please contact us for an instantly price!

Production Equipment

Production capacity: Xienuo Enterprise has a total of 25 state-of-the-art cold rolling, cast rolling, hot continuous rolling, foil rolling and extrusion production lines, including 6 casting and rolling lines, 4 continuous casting and rolling lines, and 3 coating production lines. 2 anodizing production lines, and more than 300 sets of production equipment such as rewinding machines, rounding machines, and slitting machines.

It can achieve an annual production capacity of 100,000 tons of aluminum plates, 100,000 tons of aluminum coils, 80,000 tons of aluminum foils, 50,000 tons of aluminum circle discs, and 50,000 tons of other aluminum products.

Our Services

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: The main managers in different divisions of the company all have the senior or middle titles, they will provide you the corresponding professional services.

We are here for you!