Aluminum strip for transformer

Alloy:1050 1060 1070 1100

Temper:O

Thickness:Customizable

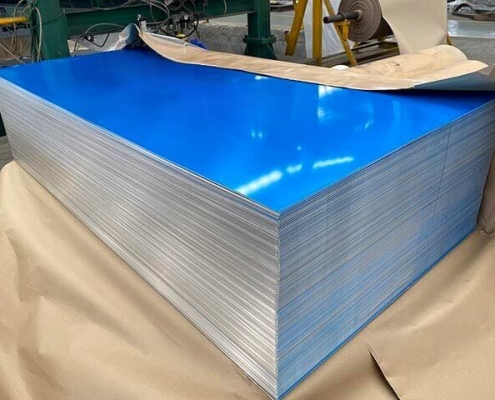

Surface:Mill finish surface, Color coated surface, Anodized surface.

Shape:Horizontal rectangle, Vertical rectangle, Square,Circle, Triangle, Pentagon, Octagon.

Aluminum strip is the main raw material in transformer winding. Different foil width combinations are designed according to actual needs. Aluminum strip used for transformer windings has good ductility and thermal conductivity, which can significantly improve the heat dissipation performance of the transformer.

How is aluminum strip used in transformer windings?

Aluminum strip for transformer winding, also known as transformer aluminum strip, is mainly used in dry-type and oil-immersed transformer manufacturing industries.

Aluminum strips used for transformer windings are available in thicknesses ranging from 0.2 mm to 3.5 mm and widths ranging from 10 mm to 1600 mm.

These strips are wrapped around an insulating material such as paper, kraft paper, Mylar, or glass cloth.

Transformer aluminum strip has high conductivity, good corrosion resistance and beautiful appearance. It is an indispensable material in the process of producing transformers.

No matter what size or tight tolerance you need for transformer aluminum strip, xienuo can meet your requirements!

What alloys are commonly used in transformer aluminum strips?

1.1050 aluminum strip in transformer

1050 O aluminum strip in transformers is the most commonly used material in transformers.

1050 O aluminum strip has high electrical and thermal conductivity. In the actual application process of transformers, 1050O aluminum strips are often used as supporting materials to form transformer windings, which can reduce the losses of the transformer and improve the performance of the transformer.

2.1060 O aluminum strip for transformer winding

Transformer windings use 1060O aluminum strips with a content of 99.6%. They are mainly used in some high and low voltage electrical equipment, such as various transformer windings. The common state is O state, so it is also called aluminum strip for transformer winding.

1060 O aluminum alloy has high plasticity, corrosion resistance, electrical conductivity and thermal conductivity.

3.What is the 1100 O aluminum strip used for transformer winding

1100 O aluminum strip for transformer windings has the advantages of high electrical conductivity, good corrosion resistance, high thermal conductivity, and large elongation ratio.

The annealing state is O.

1100 aluminum strip for transformer windings can be used to make dry-type transformers, oil-immersed transformers and reactor windings.

1050 Aluminum Strip

1060 Aluminum Strip

Aluminum Strip For Transformer

What are the advantages of using aluminum strip for transformer winding?

The conductivity of aluminum strip used in transformer windings is as high as 61%, while the conductivity of pure copper is only 58%.

This means that with the same amount of conductivity, the aluminum strip is lighter and thinner.

How to choose aluminum strip for transformer winding?

If you want to buy aluminum strips for transformers, try to choose aluminum strips that have their own factories and production lines, so that quality and output can be controlled from production to processing.

How to choose high-quality aluminum strip suppliers?

1.Most large manufacturers have their own inspection team, who will conduct strict inspection on all goods before shipment. You can inquire whether corresponding services can be provided.

2.If possible, it is best to visit their factory in person and inspect the production line and warehouse in person. It is very important to understand how they control quality from processing to delivery.

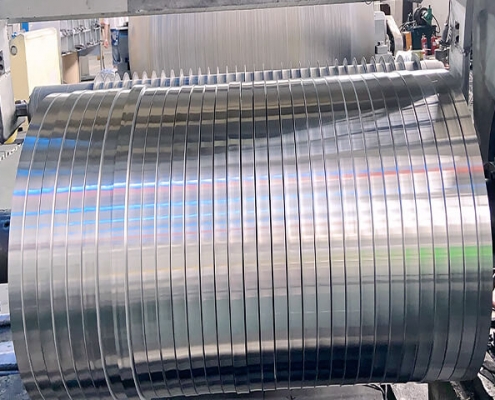

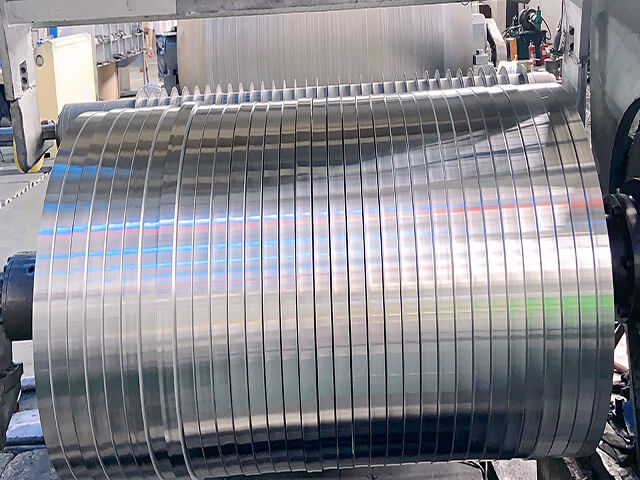

Production Equipment

Production capacity: Xienuo Enterprise has a total of 25 state-of-the-art cold rolling, cast rolling, hot continuous rolling, foil rolling and extrusion production lines, including 6 casting and rolling lines, 4 continuous casting and rolling lines, and 3 coating production lines. 2 anodizing production lines, and more than 300 sets of production equipment such as rewinding machines, rounding machines, and slitting machines.

It can achieve an annual production capacity of 100,000 tons of aluminum plates, 100,000 tons of aluminum coils, 80,000 tons of aluminum foils, 50,000 tons of aluminum circle discs, and 50,000 tons of other aluminum products.

Our Services

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: The main managers in different divisions of the company all have the senior or middle titles, they will provide you the corresponding professional services.

We are here for you!