What are the differences between cold-rolled aluminum plates and hot-rolled aluminum plates?

In the field of aluminum plates, the production process of aluminum plates can be divided into cold-rolled aluminum plates and hot-rolled aluminum plates.

The production processes of hot-rolled aluminum sheets and cold-rolled aluminum sheets are different

Hot rolled aluminum plate: aluminum ingot – melted and cast into flat ingot – milled – homogenized annealing – hot rolled into strip

Cold rolled aluminum plate: aluminum ingot – smelting – rolled into strip by casting and rolling mill

Hot-rolled aluminum sheets are pressed repeatedly from flat ingots into strips. The metal ions react fully and have strong mechanical properties and ductility. They are suitable for deep processing and areas with higher performance requirements.

Other differences between hot-rolled aluminum plates and cold-rolled aluminum plates:

- Price: Cold-rolled aluminum plates have a simple process and are cheaper than hot-rolled aluminum plates;

- Different properties: hot-rolled aluminum plates have good surface quality, strong mechanical properties and ductility, and good oxidation effects;

- Different uses: cold-rolled aluminum plates are mostly used in molds, while hot-rolled aluminum plates are suitable for stamping and stretching;

How to distinguish between hot rolled aluminum plate and cold rolled aluminum plate?

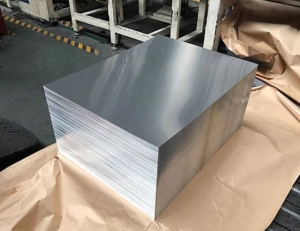

- Generally, the surface of hot-rolled products is brighter

- Test elongation.

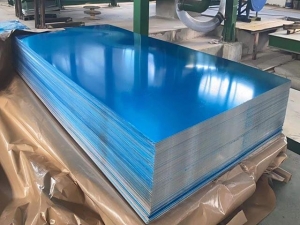

Xienuo Aluminum can produce 1-8 series aluminum plates with thickness of 0.2mm-600mm and width of 80mm-2500mm, undertake orders of 3-500 tons, and export to the world.